Digital Twin Technology

Master Digital Twin Technology: Build Virtual Replicas with IoT & AI for Industry 4.0, Healthcare & Smart Cities. Become a Systems/Simulation Engineer View Course Curriculum

Price Match Guarantee

Full Lifetime Access

Access on any Device

Technical Support

Secure Checkout

Course Completion Certificate

View Course Curriculum

Price Match Guarantee

Full Lifetime Access

Access on any Device

Technical Support

Secure Checkout

Course Completion Certificate

97% Started a new career

BUY THIS COURSE (

97% Started a new career

BUY THIS COURSE (GBP 12 GBP 29 )-

87% Got a pay increase and promotion

87% Got a pay increase and promotion

Students also bought -

-

- Industrial AI

- 30 Hours

- GBP 12

- 333 Learners

-

- Internet of Things (IoT) Basics

- 10 Hours

- GBP 12

- 98 Learners

-

- Premium Career Track - Chief Technology Officer (CTO)

- 1000 Hours

- GBP 39

- 5214 Learners

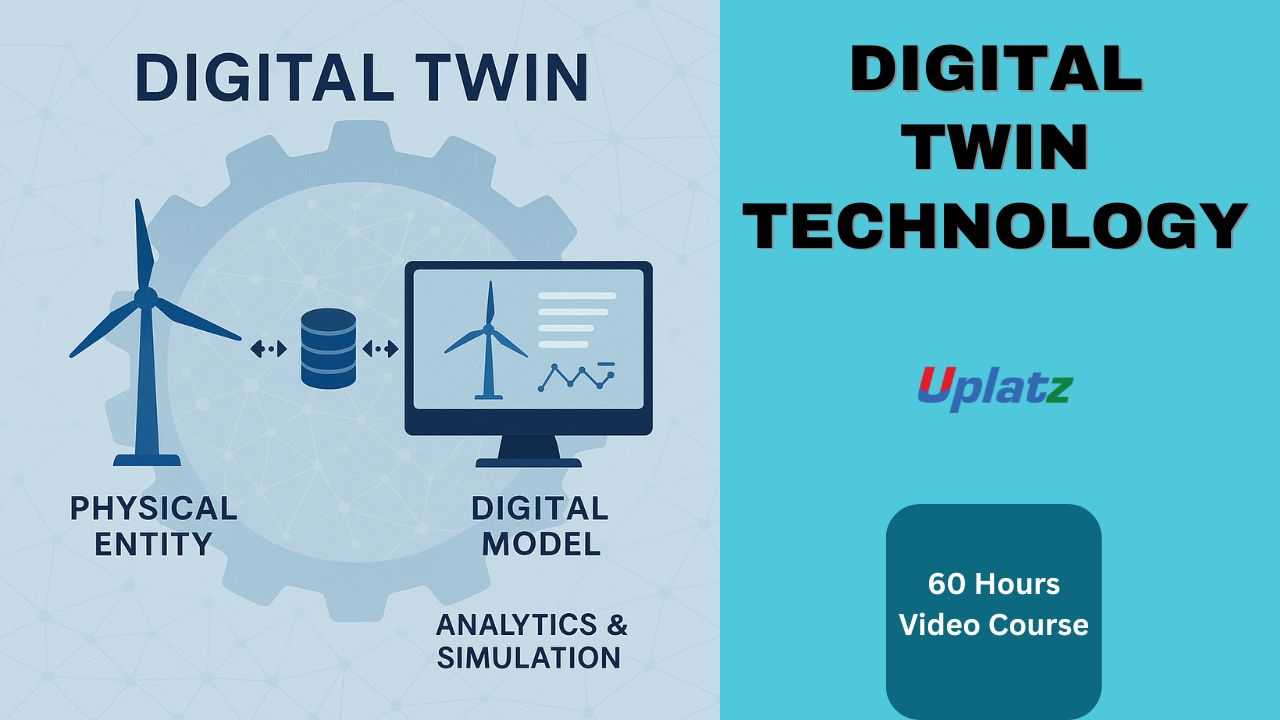

Digital Twin Technology – Online Course

Digital Twin Technology From Concepts to Real-World Applications is a transformative, self-paced online course designed to equip learners with the knowledge and skills necessary to harness the power of Digital Twin Technology—one of the most disruptive innovations reshaping industries today. With a blend of expert-led video lectures, practical projects, and guided learning paths, this course allows you to explore, experiment with, and master the digital twin ecosystem at your own pace.

Digital Twin Technology involves creating real-time digital counterparts of physical systems, processes, or objects. These virtual replicas are used to simulate, analyze, and optimize performance—offering insights that improve operational efficiency, enable predictive maintenance, and reduce risks. From smart factories and autonomous vehicles to intelligent healthcare systems and urban infrastructure, digital twins are playing a pivotal role in transforming the way organizations design, operate, and evolve their assets.

This course is built to deliver a comprehensive learning experience that starts with the fundamentals and gradually deepens into more advanced concepts. You'll learn how digital twins integrate technologies such as Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), Big Data, and Cloud Computing to bridge the gap between the physical and digital worlds. You’ll also explore the architecture, lifecycle, implementation techniques, and real-world use cases across various industries.

By the end of the course, you’ll not only understand how Digital Twins work, but also be capable of designing, developing, deploying, and managing them for specific applications—making you a valuable asset in the digital transformation journey of any organization. Upon successful completion, you’ll receive a Course Completion Certificate, validating your expertise and readiness to apply your knowledge professionally.

Who This Course is For

This course is ideally suited for:

- Engineers (Mechanical, Electrical, Civil, Industrial, and Systems) seeking to understand the role of digital twins in design, simulation, and operations.

- Data Scientists and Analysts who want to work with real-time data, simulation models, and predictive analytics in a practical context.

- IoT and AI Practitioners aiming to combine their skills with digital twin frameworks to build intelligent systems.

- IT Professionals and Cloud Architects looking to explore integration of cloud-based infrastructure with physical assets.

- Project Managers, Consultants, and Business Leaders involved in digital transformation, Industry 4.0, or smart city initiatives.

- Students and Tech Enthusiasts keen on diving into a future-proof and high-demand technology field.

Whether you're entering the domain of digital twins for the first time or expanding your existing skill set, this course provides a balanced mix of theory, technology, and application.

What You Will Learn

This course is structured to walk you through the digital twin journey—beginning with foundational knowledge, moving through technology enablers like IoT sensors and AI analytics, and ending with design and implementation strategies. You will explore key concepts such as:

- What is a Digital Twin and how does it differ from simulations?

- Core components of a digital twin system

- Real-time data collection, integration, and processing

- Predictive analytics and anomaly detection

- Twin creation for machines, people, and processes

- Applications in manufacturing, healthcare, energy, transportation, and smart cities

- Challenges in scaling, data security, and performance optimization

- Deployment using cloud platforms like Azure Digital Twins, AWS IoT TwinMaker, and others

You’ll also get hands-on experience through practical exercises and mini-projects that allow you to simulate real-world scenarios and build your own basic digital twin prototypes.

How to Use This Course Effectively

This self-paced course is designed to give you maximum flexibility without compromising on learning outcomes. Here’s how to get the most from it:

1. Define Your Learning Goals

Before you start, clarify why you’re taking this course. Are you preparing for a job role in smart manufacturing? Trying to build a prototype for your company? Interested in applying digital twins in urban planning? Your personal objectives will guide how you navigate the course content and focus your attention.

2. Follow the Structured Pathway

The course modules are arranged in a logical order—from the basics to advanced applications. Even if you have prior experience, it’s recommended to follow the sequence to ensure you don’t miss any foundational elements that are critical for understanding the later modules.

3. Engage Actively With Hands-On Projects

Digital Twin Technology is best learned through doing. Be sure to complete all exercises and labs included in the course. Set up your own development environment and try to replicate the projects independently. This will help reinforce theoretical knowledge with practical application.

4. Take Notes and Create Summaries

Maintain a digital or physical notebook to jot down key concepts, definitions, frameworks, and takeaways from each module. This will help with revision and also serve as a quick reference when you apply what you’ve learned on the job or in future projects.

5. Work on a Capstone Project

As you progress, identify a domain you're passionate about and start building a simple digital twin prototype. This could be a smart home system, a predictive maintenance solution for a motor, or a patient health monitor. Document your design, challenges, and learnings as part of your professional portfolio.

6. Interact With the Community

If your course platform offers a discussion forum or peer network, make use of it. Share ideas, ask questions, respond to others, and gain new perspectives. Collaborative learning is often more effective and enjoyable.

7. Revisit Complex Topics

Some concepts—like real-time data synchronization or integrating AI into twins—may require deeper reflection. Don’t hesitate to revisit video lectures or supplementary readings until you’re confident in your understanding.

8. Apply Knowledge in Your Work Environment

Where possible, try to apply your learning in your current job or internship. Even a small pilot project using sensor data or predictive analytics can be a great start and may open doors to larger opportunities within your organization.

9. Prepare for Certification

As you complete the course, review the materials thoroughly to ensure you’re ready to take the final assessment. The Course Completion Certificate is not only a testament to your effort but also a valuable credential to highlight on your resume and LinkedIn profile.

By the end of this course, you'll have gained a strong grasp of Digital Twin Technology—both as a concept and as a practical tool. You’ll be well-equipped to drive innovation, lead digital initiatives, and contribute to the future of connected, intelligent systems across any industry.

Whether you're reimagining urban infrastructure, optimizing manufacturing workflows, or managing healthcare devices, this course empowers you to become a strategic thinker and technical expert in one of the most impactful digital technologies of the decade.

By the end of this course, learners will:

- Grasp Digital Twin Fundamentals – Concepts, types, and industry applications.

- Master Core Technologies – IoT, AI, big data, and cloud computing in Digital Twins.

- Build Digital Twins – Hands-on projects using tools like AWS TwinMaker and Azure Digital Twins.

- Apply Industrial Solutions – Implement Digital Twins in manufacturing, healthcare, and smart cities.

- Ensure Security & Compliance – Address privacy and lifecycle management challenges.

- Explore Advanced Trends – Cognitive Digital Twins, 5G integration, and the Metaverse.

- Prepare for Certification & Careers – Gain skills for high-demand roles in emerging tech.

Module 1: Introduction to Digital Twin Technology

- What is a Digital Twin? History, types, and key components.

- Digital Twin vs. Simulation vs. IoT vs. AI.

- Industry applications: Healthcare, manufacturing, smart cities.

Module 2: Core Technologies Behind Digital Twins

- IoT’s role: Sensors, connectivity, and real-time data.

- Big data, cloud, and edge computing for Digital Twins.

- AI/ML for predictive analytics and automation.

Module 3: Building Digital Twins – Hands-On

- Steps to create a Digital Twin: Data collection to deployment.

- Tools: Siemens MindSphere, AWS TwinMaker, Azure Digital Twins.

- Project: Develop a simple Digital Twin.

Module 4: Industrial Applications

- Smart manufacturing (Industry 4.0) and supply chain optimization.

- Healthcare: Surgical simulations and patient monitoring.

- Energy, automotive, and aerospace use cases.

Module 5: Engineering & Security

- Designing scalable Digital Twin architectures.

- Cybersecurity, privacy, and compliance.

- Lifecycle management and predictive maintenance.

Module 6: Advanced Concepts

- Cognitive Digital Twins and the Metaverse.

- 5G integration and edge AI for real-time processing.

Module 7: Case Studies

- Manufacturing optimization, smart cities, and autonomous vehicles.

Module 8: Future Trends

- Ethical considerations and career pathways in Digital Twin technology.

Upon completion, learners receive a Course Completion Certificate from Uplatz, validating expertise in Digital Twin design and implementation. This certification:

- Demonstrates proficiency in IoT, AI, and cloud-based Digital Twin platforms.

- Prepares for advanced certifications like Siemens MindSphere or Microsoft Azure Digital Twins.

- Enhances career prospects in Industry 4.0, smart infrastructure, and AI-driven analytics.

Completing this Digital Twin Technology course unlocks high-growth career opportunities across industries adopting this transformative technology. Digital Twin expertise is in high demand as organizations seek to optimize operations, reduce costs, and drive innovation through virtual simulations.

Top Career Paths for Digital Twin Professionals:

- Digital Twin Engineer

- Role: Design, develop, and deploy Digital Twins for industrial and commercial applications.

- Skills Needed: IoT integration, 3D modeling, real-time data analytics, and platform expertise (e.g., Siemens MindSphere, Azure Digital Twins).

- Industries: Manufacturing, aerospace, automotive, and energy.

- IoT Solutions Architect

- Role: Build end-to-end IoT systems that feed data into Digital Twins for predictive maintenance and automation.

- Skills Needed: Sensor networks, cloud computing (AWS/Azure), edge AI, and cybersecurity.

- Industries: Smart cities, logistics, healthcare.

- AI & Simulation Specialist

- Role: Enhance Digital Twins with machine learning for self-optimizing systems (e.g., cognitive Digital Twins).

- Skills Needed: Python, TensorFlow/PyTorch, physics-based modeling, and computational simulations.

- Industries: Robotics, autonomous vehicles, biomedical engineering.

- Smart City Consultant

- Role: Implement Digital Twins for urban planning, traffic management, and sustainable infrastructure.

- Skills Needed: GIS mapping, big data analytics, and stakeholder collaboration.

- Industries: Government, urban development, environmental tech.

- Predictive Maintenance Analyst

- Role: Use Digital Twins to monitor equipment health and prevent failures in real time.

- Skills Needed: Condition monitoring, failure mode analysis, and CMMS software.

- Industries: Oil & gas, utilities, industrial manufacturing.

- Digital Twin Product Manager

- Role: Lead cross-functional teams to develop commercial Digital Twin solutions.

- Skills Needed: Agile methodologies, stakeholder management, and market analysis.

- Industries: SaaS, industrial automation, tech startups.

Emerging Roles:

- Metaverse Developer (Creating immersive Digital Twins for virtual worlds)

- Climate Modeling Specialist (Using Digital Twins for environmental simulations)

- Healthcare Digital Twin Expert (Personalized medicine and hospital operations)

- What is a Digital Twin, and how does it differ from simulation?

A Digital Twin is a dynamic, real-time virtual replica of a physical system, while simulation is a static model for testing scenarios. - How do IoT and AI enhance Digital Twins?

IoT provides real-time data from sensors, and AI enables predictive analytics and autonomous decision-making. - Name key tools for building Digital Twins.

Siemens MindSphere, AWS TwinMaker, Azure Digital Twins, and PTC ThingWorx. - What are the challenges in Digital Twin implementation?

Data integration, scalability, security, and interoperability across platforms. - How are Digital Twins used in healthcare?

For personalized treatment plans, surgical simulations, and medical device monitoring. - Explain predictive maintenance with Digital Twins.

Real-time data from equipment predicts failures, reducing downtime and costs. - What role does 5G play in Digital Twins?

Enables high-speed, low-latency data processing for real-time updates. - How do Digital Twins support smart cities?

By optimizing traffic, energy use, and infrastructure planning through virtual models. - What are Cognitive Digital Twins?

AI-driven twins that learn, adapt, and autonomously optimize processes. - Describe a Digital Twin project you’d design.

Example: A twin for a wind farm, using IoT sensors and AI to predict maintenance needs and optimize energy output.