Bundle Combo - SAP EWM (ECC and S/4HANA)

SAP EWM module is used to efficiently manage inventory, processing of goods movement and to control inbound & outbound processes in the warehouse.Preview Bundle Combo - SAP EWM (ECC and S/4HANA) course

Price Match Guarantee Full Lifetime Access Access on any Device Technical Support Secure Checkout Course Completion Certificate 90% Started a new career

BUY THIS COURSE (

90% Started a new career

BUY THIS COURSE (GBP 22 GBP 49 )-

81% Got a pay increase and promotion

81% Got a pay increase and promotion

Students also bought -

-

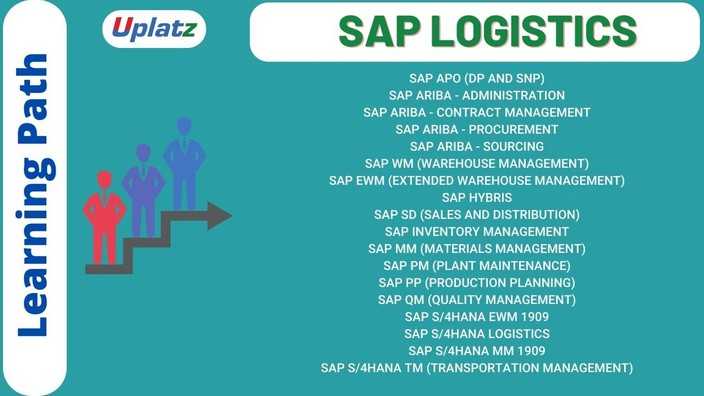

- Learning Path - SAP Logistics

- 400 Hours

- GBP 29

- 2299 Learners

-

- Bundle Combo - SAP SD (ECC and S/4HANA)

- 50 Hours

- GBP 22

- 277 Learners

-

- Career Path - SAP Functional Consultant

- 500 Hours

- GBP 99

- 7893 Learners

Courses included in Bundle Combo – SAP EWM (ECC and S/4HANA) are:

1).SAP EWM (Extended Warehouse Management)

2).SAP S/4HANA EWM 1909

SAP EWM, Extended Warehouse Management (EWM), is a part of SAP Supply Chain Management like Warehouse Management System, but it provides more robust and advanced features to manage key activities in a warehouse. SAP EWM is used to efficiently manage inventory in a warehouse and for supporting processing of goods movements. It allows to subdivide SAP Inventory Management Storage Locations in different specific places and at the same time it offers all related functionality for the placement in Warehouses (Put away processes) and the removal from them (Stock Removal processes).

SAP Extended Warehouse Management (SAP EWM) is a comprehensive solution for managing complex warehouse and logistics processes. It goes beyond the capabilities of the Warehouse Management (WM) module in traditional SAP ERP systems. SAP S/4HANA EWM, on the other hand, is the warehouse management component specifically designed for the SAP S/4HANA ERP suite. Here's a breakdown of the two:

1).SAP EWM (ECC based)

SAP EWM is a standalone application that can be integrated with various SAP and non-SAP backend systems. It provides advanced capabilities for managing various warehouse operations, including:

Inbound and outbound processing, Inventory management and optimization, Yard management, Cross-docking, Slotting and rearrangement of goods, Labor management and resource optimization, Wave management and order consolidation, Advanced picking and packing strategies, Handling unit management.

SAP EWM is known for its flexibility and adaptability to complex warehouse scenarios, making it suitable for distribution centers, manufacturing plants, and other environments with intricate supply chain needs.

2).SAP S/4HANA EWM

SAP S/4HANA EWM is the embedded warehouse management solution within the SAP S/4HANA suite. It's a part of the S/4HANA core, which means it offers tight integration with other S/4HANA modules, such as procurement, sales, manufacturing, and finance. This integration provides real-time visibility and helps streamline end-to-end business processes.

Key features of SAP S/4HANA EWM:

1.Integration with SAP S/4HANA: SAP S/4HANA EWM is tightly integrated with other modules within the SAP S/4HANA suite, such as Procurement, Sales, Manufacturing, Finance, and more. This integration enables real-time data exchange and streamlined end-to-end business processes.

2.Core Warehouse Management Functionality: SAP S/4HANA EWM provides essential warehouse management capabilities, including inbound and outbound processes, inventory management, and order fulfillment. It allows you to efficiently manage goods movements, stock levels, and order processing within the warehouse.

3.Simplified Architecture: Unlike the standalone SAP EWM application, which requires a separate installation and system landscape, SAP S/4HANA EWM is a part of the S/4HANA core. This can simplify the technical landscape and reduce the complexity of maintaining separate systems.

4.User Experience: SAP S/4HANA EWM benefits from the user experience improvements and innovations that come with the SAP S/4HANA suite, such as a modern and intuitive user interface, improved analytics, and enhanced reporting capabilities.

5.Configuration and Flexibility: While SAP S/4HANA EWM may not offer the same breadth of complex warehouse management features as the standalone SAP EWM, it provides configuration options to adapt to various warehouse scenarios. It's designed to cater to a wide range of industries and business models.

6.Embedded Analytics: SAP S/4HANA EWM leverages the embedded analytics capabilities of the S/4HANA suite. This allows users to gain insights into warehouse operations, monitor performance, and make data-driven decisions directly from the same system.

7.Upgrade Path: If your organization is already using or planning to move to SAP S/4HANA as your ERP solution, choosing SAP S/4HANA EWM can offer a smoother transition and alignment with your overall SAP strategy.

For organizations looking to have warehouse management capabilities tightly integrated with their core ERP processes, S/4HANA EWM can be a suitable choice. It's important to note that the choice between SAP EWM and SAP S/4HANA EWM depends on the complexity of your warehouse operations, the level of integration you need with other business processes, and your organization's existing SAP landscape.

Course/Topic 1 - SAP EWM - all lectures

-

In this video, you will be presented with a basic understanding of what is a logical system, RFC connection and their respective configuration. You will be introduced to Plant, how to assign plant in company code and about storage location. Further, you will be preceded with warehouse known as intermittent between plant storage and EWM warehouse.

-

In the session, you will learn how to define business system and assignment of the same in logical system. You will have an understanding of EWM warehouse and its customizing. Further, you will be preceded with a mapping warehouse and pushing plant from ECC to EWM.

-

In this video, you will learn about the supply chain, supply chain unit and how the supply chain unit is mapped to the warehouse. You will also learn how to check the entire connectivity of ERP – SAP EWM configuration.

-

In the session, you will have an in-depth understanding of how the material is created in ECC, its configuration and then shifted to EWM. You will also run how to check the material in SAP EWM and configuration of extending or creating warehouse data for cuffing the material in SAP EWM system.

-

In this video, you will learn about how to CIF the vendor to SAP EWM from ECC using two transactions- CMF1 & CMF2. Further, you will be preceded by how to check whether the vendor has CIF to SAP EWM or not along with the configuration.

-

In this video, you will have a deeper knowledge of warehouse structure from warehouse number, storage type, storage section, storage bin and quantity. You will also learn the four types of storage type and their configuration. Further, you will be preceded with the creation of Storage Section and Storage Bin.

-

In the session, you will learn how to define an activity, assignment of the storage bin to new activity area. You will also learn sorting sequence for an activity area followed by Bin sorting along with the configuration of each step.

-

In the session, you will be explained in a detailed what is work center, where it can be used in the processing and its use. You will also learn the configuration of the work center for all warehouses.

-

This video serves as a break so as to allow you time to revise all previous lectures of SAP EWM.

-

In the session, you will learn about the warehouse process type and why we need this in the system. You will know how to define warehouse process type and control indicators. Further, you will be preceded with a configuration of assigning control indicators to warehouse process type.

-

In this lecture, you will be presented with the deeper understanding of what is availability group and stock type. Further, you will be preceded with how to define an availability group, configuration of stock type, assigning it to stock type and mapping location from ERP system to EWM.

-

In the session, you will learn about the storage type search location and its assignment. You will also learn how to define put away control indicators and specify storage type. Further, you will be preceded with a configuration of storage location and how to create storage section indicators.

-

In the session, you will be presented with the configuration of material and vendor to EWM followed by the configuration of purchase order in ECC, creation of inbound delivery for a purchase order in ECC and finally goods receipt in SAP EWM.

-

In the session, you will be presented with the flowchart of the entire previous lecture and a brief explanation of all topics that had been covered till now.

-

In the session, you will two processes, first how to block the bins or unblock the bins and the second process is how to do mass changes of bins followed by several steps and their respective configuration.

-

In this video, you will learn how to put the stock in the particular bin. What are the settings and configuration is required in a system from creating a new storage type to run the inbound process for a material?

-

In this video, you will have a deeper knowledge of how to scrap or block goods followed by several steps from how to define new storage type to creating warehouse to move the material into scrap bin along with their respective configuration.

-

In the session, you will learn how outbound delivery will flow from the ERP system to the SAP EWM system. Further, you will be preceded with a configuration of each ERP setting, EWM settings and integration of EWM ERP. You will also have an idea of when system is ready for the distribution of outbound delivery from ECC to EWM.

-

In the session, you will be presented with the path on how to set up ECC in organisation followed by several steps and their respective configuration and assignment.

-

In this video, you will learn how to create customer, how to create a sale order for a customer & outbound delivery for sale order. You will also learn the distribution of outbound delivery to the EWM system along with the configuration of each step.

-

In the session, you will be explained in a detailed how goods issued once the sale order created and outbound delivery in SAP EWM. You will learn how goods will be picked from EWM, how the testing will be done in the system and the use of stock removal strategy to pick the goods from the bin along with their configuration.

-

In this lecture, you will learn how goods will be picked automatically from the bin. There are different stock removals strategies, in this video; you will see how removal strategy is defined. Further, you will be preceded with standard strategy of stock removal - FIFO & LIFO along with the configuration.

-

In this video, you will learn how goods are issued directly for consumption to cost centre for partner or for internal people. You will also learn how it will be directly done in EWM and how to set up cost centre followed by pre-request and configuration of several steps and process to have direct consumption to cost centre.

-

In the session, you will have a deeper knowledge of physical inventory, where one cross check the stock to make sure physical stock is present in the system. You will also learn about the two types of it and the three types of inventory procedure to carry this process. Further, you will be preceded by steps to follow the configuration of physical inventory setting in a warehouse.

-

In the session, you will be presented with the process to carry the physical inventory in the warehouse. There are 5 steps from creating a physical inventory to checking inventory in ECC along with their respective configuration.

-

In this video, you will learn about posting changes. You will also learn about the two methods of posting changes: one in EWM and the other in ERP. Further, you will be preceded with settings and configuration of EWM and in ECC respectively.

-

This video is a continuation of the previous lecture, where you will learn the process of posting changes in ERP and EWM followed by several steps and their respective configuration.

-

In the session, you will learn about replenishment, i.e. the movement of goods from warehouse to shipment location. There are three common fields for replenishment. You will also learn about the types of replenishment and configuration of how to create replenishment followed by several steps.

-

This video is a continuation of the previous lecture, where you will learn about three types of replenishment process in detail along with their configuration and assignment.

-

In the session, you will be explained in a detailed what is cross-docking, where it can be used, types of cross-docking and configuration set up required for EWM cross-docking followed by several steps.

-

In this video, you will learn about the cross-docking process in detail. There are 8 steps in the process from creating a sale order in ECC to check purchase order & sale order in ECC followed by their respective configuration.

-

In the session, you will learn about what is slotting, what are the four types of parameters in slotting and condition techniques in slotting. Further, you will be preceded with the configuration set up required in the process to determine slotting.

-

In the session, you will learn how the slotting process will run in the real-time. The process is consisting of five steps from creating material in ECC to check material again in detail with their respective configuration.

-

In the session, you will learn about post process framework, its use as a tool for scheduling, starting and monitoring actions. You will also learn about the structure of PPF. Further, you will be preceded with PPF configuration set up in detail in three steps.

-

In the session, you will be presented with how the PPF will perform in inbound delivery. You will also learn about the PPF process in detail followed by four steps from creating a purchase order in ECC to goods receipt and print GR slip, along with their respective configuration.

Course/Topic 2 - SAP S/4HANA EWM 1909 - all lectures

-

In this first video on the SAP S/4HANA EWM course, you will get a briefing on the course contents, the objective of the training, and some basic terminologies associated with the Embedded Extended Warehouse Management system.

-

In this video, you will learn about Supply Chain Management starting with a diagrammatic representation of the high-level process of SCM, the definition of EWM, the business functions of EWM, a brief explanation on the De-Centralised EWM, EWM Master Data Distribution, the transaction data flow of De-Centralized EWM, the data transfer process between S4HANA and EWM, Warehouse Layout & many others.

-

This video is a complete practical session on Warehouse Product Maintenance and the complete work process of it will be shown by the trainer in the SAP system.

-

In this video, you will learn about the different terminologies associated with SAP Warehouse Management, whether be it the S/4HANA or EWM. Along with this, you will also learn about the different reasons for deploying Embedded EWM in SAP S/4HANA 1909 instead of Decentralized SCM EWM. Furthermore, you will also learn about the mapping process of S/4HANA Document Type to EWM Document Type.

-

In this video, you will learn about the different processes associated with the Extended Warehouse Management starting with an overview on the Inbound Process; its roles and the process flow, the Outbound Process, the 5 specific warehouse areas, WM Complex Processes, U Flow Layout Design, Slotting & Rearrangement, the difference between WM and S/4HANA EWM and many more.

-

In this session, you will learn about the Slotting & Rearrangement process in S/4HANA Embedded EWM along with the Internal Warehouse Process, Transfer Posting in EWM, Goods Receipt Process in EWM, S/4HANA EWM Master Data, and others.

-

In this video, you will learn about the different stock removal strategies such as FIFO, Stringent FIFO, LIFO, Partial Quantities & others with a detailed explanation of each of them. You will also learn about the complete work process of Storage Control.

-

This is a complete practical session on how to work on the process of Purchase Order and maintaining the Inbound Delivery in the SAP system. The trainer will be showing a step-by-step process of the complete procedure in the SAP system.

-

In this session, you will learn the configuration steps involved in the storage control of POSC with a detailed work process of it being shown in the SAP system.

-

This session will teach you on the work process of Document Flow and other in case of Storage Control in the SAP system.

-

In this video, you will learn about the Process-Oriented Storage Control in Inbound Process with an example and a diagrammatic explanation along with the Material Flow System which will be shown by the trainer in the SAP system.

-

The first part of this video is a revision of the previous sessions being held on various topics. The latter half of the session is for the Activities to be done in EWM like defining availability group, defining non-location-dependent stock type, configuration stock type, and assigning availability group to storage type. All these 4 activities will be shown by the trainer in the SAP system.

-

In this session, you will get practical lessons on the Packaging work procedure for the SAP Extended Warehouse Management system.

-

In this video, you will learn about the Post Processing Framework, commonly abbreviated as PPF, and the configuration of the Work Center in the SAP system.

-

This is the second part of the Post Processing Framework video where you will get some theoretical concepts on PPF like understanding the concept of PPF, the structure of Post Processing Framework, how PPF is used in connection with delivery processing in EWM, the configuration steps for connecting PPF to delivery processing and others.

-

This video is a practical session on Product Description and Wave Management where you will learn the complete work process in the SAP system. The trainer will be showing each and every step in the SAP system.

-

In this video, the trainer will be showing the work procedure of the physical inventory system along with the other tasks associated with it in the SAP system.

-

In this video, you will learn the Inbound and Outbound Processing associated with SAP S/4HANA EWM and its work process in the system.

-

This is a practical session where you will learn and implement the concept of the Putaway Control Indicator in the SAP system.

-

In this video, you will learn about the work procedure of Inbound Delivery associated with the Warehouse Management in the SAP system.

-

This video is a refresh session summary on the topics and agenda already covered throughout the whole course.

-

In this video, you will get a brief overview of the Warehouse Management Complex Processes along with the Warehouse Material U Flow Layout Design, High-Level Process of Supply Chain Management, and the Process Flow in SCM.

-

In this video, you will get a detailed explanation of the SAP EWM Organizational Structure, the terminologies related to the Org Structure such as Warehouse Number, Storage Type, Storage Section, Storage Bin, and Quant.

-

In this last video of the SAP S/4HANA course, you will learn about the maintenance procedure of SCM in the SAP system along with a detailed explanation on Master Data which will be shown with a detailed step-by-step procedure in the SAP system.

After the completion of this course, you will be able to:

a).Know what can be done with S/4 HANA EWM

b).Necessary Organizational Units and Master Data for working with S/4 HANA EWM

c).Understand the differences between S/4 HANA EWM and SAP WM

d).Managing key resource management in warehouse tasks effectively.

e).To perform executable tasks like work packages & other warehouse tasks.

SAP Extended Warehouse Management (EWM) in ECC and S/4HANA

This course provides an in-depth understanding of SAP Extended Warehouse Management (EWM) in both ECC and S/4HANA environments. Participants will learn key concepts, configurations, and best practices for managing warehouse operations effectively.

Week 1: Introduction to SAP EWM

a).Overview of Warehouse Management concepts

b).Differences between SAP EWM and traditional WM

c).Key features and benefits of SAP EWM

d).Understanding EWM architecture in ECC and S/4HANA

Week 2: EWM Configuration Basics

a).Basic settings for EWM configuration

b).Defining warehouse structures: Warehouse layout and storage types

c).Setting up storage bins and areas

d).Understanding organizational units in EWM

Week 3: Master Data Management in EWM

a).Overview of master data requirements

b).Creating and managing products in EWM

c).Managing packaging specifications and handling units

d).Integration of master data with ECC and S/4HANA

Week 4: Inbound and Outbound Processes

a).Configuring inbound processing: Goods receipt and putaway

b).Setting up outbound processing: Order picking and shipping

c).Understanding cross-docking and wave management

d).Hands-on exercises with inbound and outbound scenarios

Week 5: Warehouse Task and Queue Management

a).Understanding warehouse tasks and their creation

b).Managing queues and task prioritization

c).Configuring task execution and monitoring

d).Best practices for efficient task management

Week 6: Inventory Management in EWM

a).Overview of inventory management processes

b).Performing stock counting and adjustments

c).Handling stock transfers and adjustments

d).Integrating inventory management with ECC and S/4HANA

Week 7: Advanced EWM Features

a).Understanding labor management and resource planning

b).Utilizing RFID and barcode scanning in EWM

c).Configuring EWM for batch management and handling units

d).Introduction to slotting and rearrangement

Week 8: EWM Integration with S/4HANA

a).Overview of integration scenarios with S/4HANA

b).Utilizing Embedded EWM vs. Decentralized EWM

c).Configuring EWM for integration with Transportation Management

d).Hands-on exercises with integration settings

Week 9: Reporting and Analytics in EWM

a).Overview of reporting tools in EWM

b).Configuring key performance indicators (KPIs) for warehouse operations

c).Utilizing SAP Analytics Cloud for warehouse analytics

d).Best practices for effective reporting

Week 10: Implementation and Best Practices

a).Project lifecycle for SAP EWM implementation

b).Change management and user training considerations

c).Common pitfalls and troubleshooting in EWM

d).Future trends in warehouse management and EWM

Recommended Resources:

1).Textbooks:

a)."SAP Extended Warehouse Management: Functionality and Implementation" by Michael O. Schmid

b).Official SAP EWM documentation

2).Online Resources:

a).SAP Learning Hub and openSAP for courses and tutorials

3).Tools:

a).SAP EWM, S/4HANA

4).Assessment:

1).Weekly quizzes and assignments

2).Mid-term project demonstrating EWM configuration

3).Final project showcasing a comprehensive warehouse management solution using SAP EWM

The SAP EWM (ECC and S/4HANA) Certification ensures you know planning, production and measurement techniques needed to stand out from the competition.

AP Extended Warehouse Management (EWM) is used to efficiently manage inventory in the Warehouse and for supporting the processing of goods movement. It allows the company to control its Warehouse inbound and outbound processes and movement of goods in the Warehouse.

The main process in a Warehouse is incoming and outgoing materials, goods receipt and goods issue, fulfill customer orders, and distribution of goods. When a company doesn’t store any goods, then there is no need for Warehouse management to manage goods.

With the help of SAP EWM, all the goods movements are controlled by a warehouse management system and provides you the tools to monitor warehouse activities. You can also manage additional functions in the Warehouse like creating a serial number, batch number, vendor management inventory, resource optimization, and value-added services. SAP Extended Warehouse Management allows you to not only monitor the quantity of goods in Warehouse but to manage other critical functions and delivery of goods efficiently.

Modules we offer in this bundle combo.

a).SAP EWM (Extended Warehouse Management)

b).SAP S/4HANA EWM 1909

c).SAP ERP Central Component (ECC)

Uplatz online training guarantees the participants to successfully go through the SAP EWM certification provided by Uplatz. Uplatz provides appropriate teaching and expertise training to equip the participants for implementing the learnt concepts in an organization.

Course Completion Certificate will be awarded by Uplatz upon successful completion of the SAP EWM online course.

The SAP EWM consultant draws an average salary of $97,080 per year depending on their knowledge and hands-on experience. The SAP EWM job roles are in high demand and make a rewarding career.

The SAP Extended Warehouse Management (EWM) Managing Consultant is responsible for leadership and providing a successful delivery of Extended Warehouse Management system module deliverables on SAP engagements, including implementation, upgrade, and extension of existing applications.

Note that salaries are generally higher at large companies rather than small ones. Your salary will also differ based on the market you work in.

The following are the job titles

a).SAP EWM Senior Consultant

b).SAP EWM Manager

Q1.What is SAP EWM extended warehouse management?

Ans-SAP Extended Warehouse Management (EWM) is used to efficiently manage inventory in the Warehouse and for supporting processing of goods movement. It allows the company to control their Warehouse inbound and outbound processes and movement of goods in the Warehouse.

Q2.What is the SAP EWM system?

Ans-SAP EWM is part of SAP Supply Chain Management (SAP SCM) and supports inventory management and movement of goods in warehouses. The multi-client warehouse management solution was designed for large distribution centers with complex and highly automated processes.

Q3.Is SAP EWM good?

Ans-The “best of breed” warehouse solutions score well in high throughput, standalone, automated, specialist operations, where high performance is critical. In contrast, SAP EWM scores well where there is a need for a high level of integration between the warehouse, production, quality control and transport.

Q4.Explain the configuration of organisational structure SAP EWM?

Ans-In SAP ERP, a warehouse number is used to represent the physical warehouse where all the material is stored. A Warehouse number is a 3 or 4 character field in Warehouse management or EWM respectively.

Q5.Explain SAP Extended Warehouse Management EWM?

Ans-SAP EWM is used to efficiently manage inventory in Warehouse and for supporting processing of goods movement. It allows companies to control their Warehouse inbound and outbound processes and movement of goods in Warehouse.

Q6.What are the key features in SAP Warehouse Management?

Ans-Using SAP EWM, you can control warehouse activities- picking, posting and managing storage bins and good receipts.

You can set alert for- changed data before goods receipt from EWM to the ERP system, reversal or correction of the goods receipt from EWM to the ERP system and an inbound delivery split from EWM to the ERP system.

Q7.What are the different deployment options in EWM?

Ans-SAP EWM can be considered as deployed in ERP server or you can also consider it as an application in Supply chain Management landscape. SAP EWM is integrated with ERP to access transaction and master data and use of features like slotting, availability check also requires integration with CRM.

Q8.How does the SAP ERP system communicate with Extended Warehouse

Ans-SAP ERP and EWM are closely integrated with each other for transfer of transaction and master data. There are two different ways of communication.

Core Interface (CIF) −

Core interface is one of the common methods for communication between SAP SCM system and SAP Advanced Planning and Optimization APO. Master data maintained in ERP systems like customer, material and vendor which are available in ERP systems are transferred to EWM systems using Core Interface CIF communication.

Q9.What is a Storage bin?

Ans-Storage bins represent the physical location of storage space where the products are stored in Warehouse. They are at the lowest level of organization structure and when you store an item in a Warehouse you need to mention its exact location.

Q10. What is the use of Activity areas in Storage bins?

Ans-Storage bins are further categorized in the activity area. It includes activities like picking, putting away or a physical inventory. As per activity, you can assign the same storage bin to multiple activity areas.

Q11.What is SAP HANA?

Ans-SAP HANA, a SAP Product is a high performance, column oriented, in-memory relational database management system. As a database server it's main function is to store and retrieve the data requested by applications. SAP HANA provides fast and advanced analytical and transactional processing on multi-model data, in cloud and on premise.

Q12. What is the SAP S/4HANA?

Ans-S/4HANA or SAP S/4HANA is a future ready enterprise resource planning (ERP) solution which is a collection of different things and comes with built-in technologies, including machine learning, AI and analytics. "SAP Business Suite 4 SAP HANA" is abbreviated as SAP S/4HANA in short. S/4HANA runs on HANA platform or HANA database - A very popular in-memory database that offers real time processing speeds.

Q13. What are the main building blocks of S/4HANA?

Ans-S/4HANA has three main building blocks.

1).HANA Platform or HANA Database SAP S/4HANA ERP systems runs on this in-memory HANA database. It solves many problems faced by ERP.

2).S/4HANA (Business suite) an updated version of SAP business suite 7 and has built-in technologies, including AI, machine learning and analytics.

3).Fiori UI a modern user interface built into SAP S/4HANA that provides consistent look and feel across all devices and ERP systems. It helps in both employee satisfaction and productivity.

Q14. What is an in-memory database?

Ans-In-Memory databases rely primarily on main memory instead of SSDs or disks for data storage and to perform operations. In-memory databases provide minimal response time by eliminating the need of accessing the data from SSDs. In-Memory databases perform all the operations on main memory.

Q15.What is SAP HANA? Explain the key benefits of an in-memory database

Ans-SAP HANA is an in-memory high performance, column oriented relational database management system. It processes the transactions with advanced analytics on multi-model data, cloud and on-premise.

Q16. What are the features of SAP HANA?

Ans-SAP HANA offers a rich set of capabilities including:

1).Database Services - It offers various database services to reduce data management burdens. These services include Database Management, Database Administration and Database Security.

2).Multi-Model Processing - SAP HANA provides the capabilities to process complex multiple data types such as documents, graphs etc. It processes transactions with advanced analytics and provides hybrid transactional and analytical processing.

3).Application Development - You can develop real-time, intelligent applications with built-in development and run-time capabilities. It offers simplified application architecture, can use existing skills and programming languages, support of various tools like Eclipse, ABAP development tools etc.

4).Data Virtualisation - It improves the data quality with built-in data quality capabilities, offers data federation, data replication and integration capabilities. SAP HANA offers a real-time gateway to all your data across applications, cloud and storage.