SAP EWM (Extended Warehouse Management)

Learn SAP EWM module, its core concepts, features, implementation, configuration, and management of EWM system application. Become SAP EWM consultant.Preview SAP EWM (Extended Warehouse Management) course

View Course Curriculum Price Match Guarantee Full Lifetime Access Access on any Device Technical Support Secure Checkout Course Completion Certificate 84% Started a new career

BUY THIS COURSE (

84% Started a new career

BUY THIS COURSE (GBP 12 GBP 29 )-

98% Got a pay increase and promotion

98% Got a pay increase and promotion

Students also bought -

-

- SAP MM (Materials Management)

- 30 Hours

- GBP 29

- 2423 Learners

-

- Bundle Combo - SAP EWM (ECC and S/4HANA)

- 70 Hours

- GBP 22

- 526 Learners

-

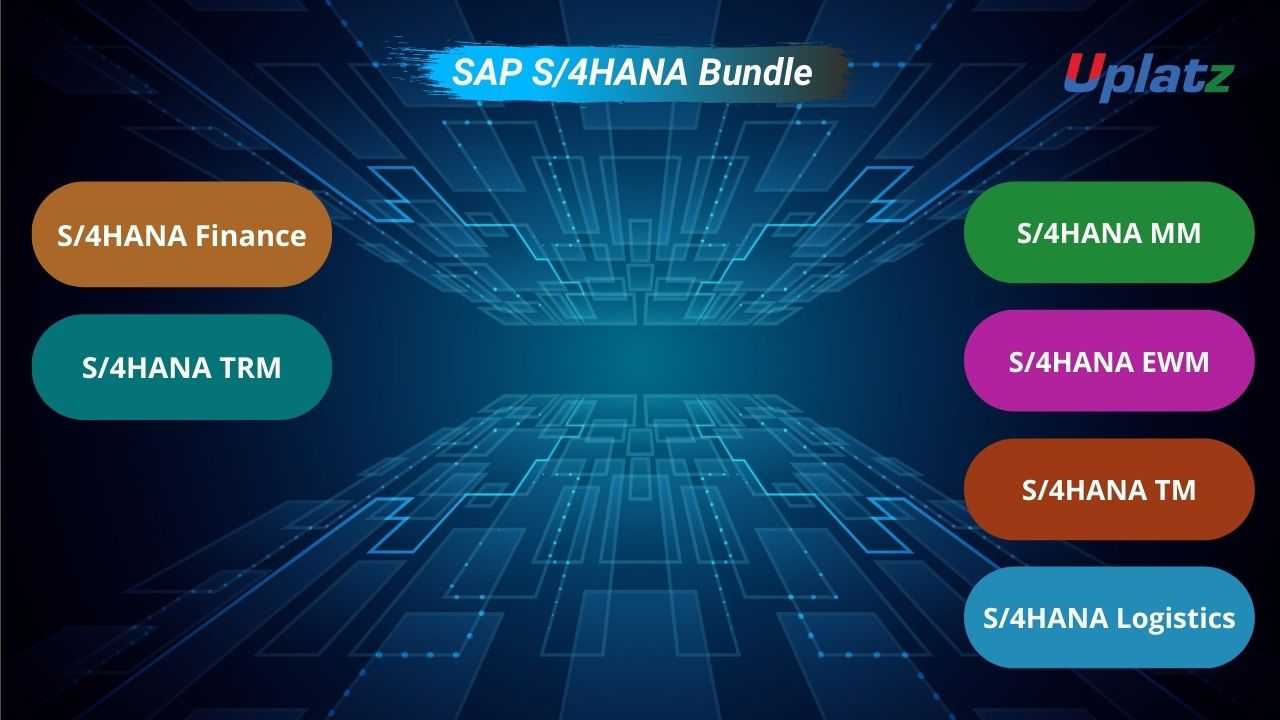

- Bundle Ultimate - SAP S/4HANA (Finance - TRM - MM - EWM - TM - Logistics)

- 150 Hours

- GBP 22

- 2091 Learners

SAP EWM (Extended Warehouse Management) forms part of SAP Supply Chain Management and provides end-to-end support for supply chain processes. SAP EWM brings together robust functionality and comprehensive process support for all types of warehouses, and is thus one of the most powerful software suites for warehouse management and control worldwide.

The principal components within SAP EWM include warehouse management and material flow control (SAP Material Flow System). EWM module facilitates new distribution procedures with which an organization can significantly reduce inventory costs while improving service quality. It provides the ability to define and map the physical layout of your warehouse and logistics centre in the system as detailed as you need.

SAP EWM depicts the individual storage facilities (high bay warehouse, small part warehouse, bulk storage, picking, etc.) as storage types and summarises them under a warehouse number. With SAP EWM your stock information can be managed due to storage location level for all products.

SAP EWM is used for processing, managing and controlling the full range of warehouse process. SAP EWM allows real-time, effective management and control of one specific link in the supply chain—the warehouse. To do so, the software manages everything from the entry of the material to the dispatch of the finished product, by way of quality control decision-making through to manufacturing consumption, transfers between warehouses, production orders, inventories and any internal movements.

Key features and functionalities of SAP EWM include:

1. Warehouse Structure Management: SAP EWM allows users to define and manage complex warehouse structures, including storage bins, storage types, storage sections, and work centers.

2. Inventory Management: It provides robust inventory management capabilities, allowing organizations to track the movement and storage of goods within the warehouse. This includes support for different valuation methods and inventory counting strategies.

3. Resource Management: Efficient allocation of resources, such as labor and equipment, is a critical aspect of warehouse management. SAP EWM helps optimize resource usage through features like labor management, task interleaving, and resource scheduling.

4. Inbound and Outbound Processing: SAP EWM supports comprehensive inbound and outbound processing, including goods receipt, goods issue, and cross-docking. It facilitates streamlined processes for receiving, putaway, picking, packing, and shipping.

5. Cross-Docking: Cross-docking is the practice of moving goods directly from the receiving dock to the shipping dock without intermediate storage. SAP EWM supports various cross-docking scenarios to enhance efficiency.

6. Wave Management: Wave management allows businesses to group and process multiple orders or tasks together to optimize warehouse operations. This helps in maximizing efficiency in picking and other tasks.

7. Slotting and Replenishment: SAP EWM provides features for intelligent slotting, which involves determining the optimal placement of goods in the warehouse. Additionally, it supports automated replenishment processes to maintain optimal stock levels.

8. Integration with SAP ERP: SAP EWM is tightly integrated with other SAP modules, including SAP ERP (Enterprise Resource Planning), allowing seamless data exchange and coordination between different business processes.

9. Advanced Analytics and Reporting: The system offers analytical tools and reporting capabilities to provide insights into warehouse performance, helping businesses make informed decisions and continuously improve their operations.

10. Radio-Frequency Identification (RFID) and Barcode Integration: Integration with RFID and barcode technologies helps in accurate and efficient data capture and tracking of goods within the warehouse.

SAP EWM is suitable for businesses that require advanced warehouse management capabilities and want to optimize their supply chain processes. It's often used in industries with complex distribution networks, high-volume order fulfillment, and a need for real-time visibility into inventory and warehouse operations. With the EWM solution, the aim is to offer a standardised way of handling any and all logistics processes with as few customised developments as possible.

In this comprehensive SAP EWM course offered by Uplatz, you will take a deep-dive into SAP EWM module and will get in-depth understanding of the core concepts, features, implementation, configuration, and management of EWM system application.

Course/Topic - SAP EWM - all lectures

-

In this video, you will be presented with a basic understanding of what is a logical system, RFC connection and their respective configuration. You will be introduced to Plant, how to assign plant in company code and about storage location. Further, you will be preceded with warehouse known as intermittent between plant storage and EWM warehouse.

-

In the session, you will learn how to define business system and assignment of the same in logical system. You will have an understanding of EWM warehouse and its customizing. Further, you will be preceded with a mapping warehouse and pushing plant from ECC to EWM.

-

In this video, you will learn about the supply chain, supply chain unit and how the supply chain unit is mapped to the warehouse. You will also learn how to check the entire connectivity of ERP – SAP EWM configuration.

-

In the session, you will have an in-depth understanding of how the material is created in ECC, its configuration and then shifted to EWM. You will also run how to check the material in SAP EWM and configuration of extending or creating warehouse data for cuffing the material in SAP EWM system.

-

In this video, you will learn about how to CIF the vendor to SAP EWM from ECC using two transactions- CMF1 & CMF2. Further, you will be preceded by how to check whether the vendor has CIF to SAP EWM or not along with the configuration.

-

In this video, you will have a deeper knowledge of warehouse structure from warehouse number, storage type, storage section, storage bin and quantity. You will also learn the four types of storage type and their configuration. Further, you will be preceded with the creation of Storage Section and Storage Bin.

-

In the session, you will learn how to define an activity, assignment of the storage bin to new activity area. You will also learn sorting sequence for an activity area followed by Bin sorting along with the configuration of each step.

-

In the session, you will be explained in a detailed what is work center, where it can be used in the processing and its use. You will also learn the configuration of the work center for all warehouses.

-

This video serves as a break so as to allow you time to revise all previous lectures of SAP EWM.

-

In the session, you will learn about the warehouse process type and why we need this in the system. You will know how to define warehouse process type and control indicators. Further, you will be preceded with a configuration of assigning control indicators to warehouse process type.

-

In this lecture, you will be presented with the deeper understanding of what is availability group and stock type. Further, you will be preceded with how to define an availability group, configuration of stock type, assigning it to stock type and mapping location from ERP system to EWM.

-

In the session, you will learn about the storage type search location and its assignment. You will also learn how to define put away control indicators and specify storage type. Further, you will be preceded with a configuration of storage location and how to create storage section indicators.

-

In the session, you will be presented with the configuration of material and vendor to EWM followed by the configuration of purchase order in ECC, creation of inbound delivery for a purchase order in ECC and finally goods receipt in SAP EWM.

-

In the session, you will be presented with the flowchart of the entire previous lecture and a brief explanation of all topics that had been covered till now.

-

In the session, you will two processes, first how to block the bins or unblock the bins and the second process is how to do mass changes of bins followed by several steps and their respective configuration.

-

In this video, you will learn how to put the stock in the particular bin. What are the settings and configuration is required in a system from creating a new storage type to run the inbound process for a material?

-

In this video, you will have a deeper knowledge of how to scrap or block goods followed by several steps from how to define new storage type to creating warehouse to move the material into scrap bin along with their respective configuration.

-

In the session, you will learn how outbound delivery will flow from the ERP system to the SAP EWM system. Further, you will be preceded with a configuration of each ERP setting, EWM settings and integration of EWM ERP. You will also have an idea of when system is ready for the distribution of outbound delivery from ECC to EWM.

-

In the session, you will be presented with the path on how to set up ECC in organisation followed by several steps and their respective configuration and assignment.

-

In this video, you will learn how to create customer, how to create a sale order for a customer & outbound delivery for sale order. You will also learn the distribution of outbound delivery to the EWM system along with the configuration of each step.

-

In the session, you will be explained in a detailed how goods issued once the sale order created and outbound delivery in SAP EWM. You will learn how goods will be picked from EWM, how the testing will be done in the system and the use of stock removal strategy to pick the goods from the bin along with their configuration.

-

In this lecture, you will learn how goods will be picked automatically from the bin. There are different stock removals strategies, in this video; you will see how removal strategy is defined. Further, you will be preceded with standard strategy of stock removal - FIFO & LIFO along with the configuration.

-

In this video, you will learn how goods are issued directly for consumption to cost centre for partner or for internal people. You will also learn how it will be directly done in EWM and how to set up cost centre followed by pre-request and configuration of several steps and process to have direct consumption to cost centre.

-

In the session, you will have a deeper knowledge of physical inventory, where one cross check the stock to make sure physical stock is present in the system. You will also learn about the two types of it and the three types of inventory procedure to carry this process. Further, you will be preceded by steps to follow the configuration of physical inventory setting in a warehouse.

-

In the session, you will be presented with the process to carry the physical inventory in the warehouse. There are 5 steps from creating a physical inventory to checking inventory in ECC along with their respective configuration.

-

In this video, you will learn about posting changes. You will also learn about the two methods of posting changes: one in EWM and the other in ERP. Further, you will be preceded with settings and configuration of EWM and in ECC respectively.

-

This video is a continuation of the previous lecture, where you will learn the process of posting changes in ERP and EWM followed by several steps and their respective configuration.

-

In the session, you will learn about replenishment, i.e. the movement of goods from warehouse to shipment location. There are three common fields for replenishment. You will also learn about the types of replenishment and configuration of how to create replenishment followed by several steps.

-

This video is a continuation of the previous lecture, where you will learn about three types of replenishment process in detail along with their configuration and assignment.

-

In the session, you will be explained in a detailed what is cross-docking, where it can be used, types of cross-docking and configuration set up required for EWM cross-docking followed by several steps.

-

In this video, you will learn about the cross-docking process in detail. There are 8 steps in the process from creating a sale order in ECC to check purchase order & sale order in ECC followed by their respective configuration.

-

In the session, you will learn about what is slotting, what are the four types of parameters in slotting and condition techniques in slotting. Further, you will be preceded with the configuration set up required in the process to determine slotting.

-

In the session, you will learn how the slotting process will run in the real-time. The process is consisting of five steps from creating material in ECC to check material again in detail with their respective configuration.

-

In the session, you will learn about post process framework, its use as a tool for scheduling, starting and monitoring actions. You will also learn about the structure of PPF. Further, you will be preceded with PPF configuration set up in detail in three steps.

-

In the session, you will be presented with how the PPF will perform in inbound delivery. You will also learn about the PPF process in detail followed by four steps from creating a purchase order in ECC to goods receipt and print GR slip, along with their respective configuration.

1. Insights on Basic ERP and EWM Integration

2. Gain knowledge on Warehouse Structure and EWM Master Data

3. Understand Inbound processing using EWM

4. Learn QIE and ERP Quality Management

5. Gain knowledge Good Receipts Process

6. Understand the concept of Yard Management in Shipping and Receiving

7. Learn how to Integrate Delivery Document and create a rule for Warehouse order

8. Understand how to Post Changes, Stock Transfers and Replenishment

1. WAREHOUSING STRUCTURES AND MASTER DATA

· Differentiating the SAP Solutions for Warehouse Management

· Outlining Organizational Structures

· Maintaining Master Data for SAP EWM

2. BASIC PROCESSES IN SAP EWM

· Processing Goods Received

· Processing Goods for Shipping

3. WAREHOUSE MONITORING AND PROCESSING WITH MOBILE DEVICES

· Managing the Warehouse

· Applying Storage Control

· Employing Serial Numbers

· Processing Batches

· Mapping Quality Inspection Processes

· Applying Value-Added Services

4. WAREHOUSE ORGANIZATION

· Performing Slotting

· Applying Replenishment Methods

· Performing a Physical Inventory

5. OPTIMIZATION OF RESOURCES

· Applying Wave Management

· Applying Labor Management

· Executing the Production Supply Process

· Executing Expected Goods Receipts Processes

· Applying Cross Docking

6. WAREHOUSE EXTENSIONS

· Planning the Shipping and Receiving of Products

· Controlling the Material Flow System (MFS)

7. COMBINED INBOUND AND OUTBOUND PROCESSES

· Executing an End-to-End Process with SAP EWM

8. THE EXTENDED WAREHOUSE MANAGEMENT (EWM) SYSTEM ENVIRONMENT

· Outlining the Basics of EWM

9. INTEGRATION

· Setting Up the Integration Between SAP ERP and SAP EWM

· Setting Up Delivery Document Integration

10. STRUCTURAL ELEMENTS AND MASTER DATA

· Creating Structural Elements in EWM

· Creating Storage Bins

· Creating Work Centers

· Transferring Master Data from ERP to EWM using the APO Core Interface

· Creating Warehouse Product Master Data

· Creating Packaging Specifications

11. WAREHOUSE PROCESS TYPES

· Applying Warehouse Process Types

12. GOODS RECEIPT

· Outlining Goods Receipt Processes in EWM

· Setting Up Availability Groups for Inventory Management (IM)

· Configuring Direct Putaway

· Applying Putaway Rules

· Checking Capacities

13. GOODS ISSUE

· Outlining the Goods Issue Process in EWM

· Applying the Stock Removal Strategies

· Configuring Pick Denials

· Processing Batch Managed Products in EWM

· Combining Items in Waves

· Implementing Two-Step Picking

14. STORAGE CONTROL

· Outlining Storage Control

· Configuring Process-Oriented Storage Control

· Configuring Layout-Oriented Storage Control

15. WAREHOUSE ORDER CREATION

· Creating Warehouse Orders

16. POSTING CHANGES, STOCK TRANSFERS, AND REPLENISHMENT

· Performing Posting Changes and Stock Transfers

· Performing Ad hoc Movements and Replenishment

17. PHYSICAL INVENTORY

· Outlining the Physical Inventory Process

· Setting Up the Procedures for Physical Inventory

18. SLOTTING

· Configuring the Slotting Process

19. POST PROCESSING FRAMEWORK (PPF)

· Outlining the Post Processing Framework

· Applying the Post Processing Framework in Delivery Processing

This SAP EWM training course is designed to help you prepare for the SAP Certified Application Associate-SAP Extended Warehouse Management 9.5 exam. The complete SAP EWM course content connects with the certification program and helps the participants to clear it with ease.

In SAP EWM Course module the participants will learn to explore the supply chain management suite solutions. In the SAP EWM course, the participants will learn about automation support for processing stock and for managing inventory inside warehouse. This seems to be an essential learning for all SAP EWM module users.

The SAP EWM Certification is an important benchmark in becoming an expert SAP EWM Consultant as the course covers supply chain logistics within your warehouse and the distribution processes. SAP EWM tutorial helps the participants to learn about extended warehouse management product thus attaining a unique SAP certification. SAP EWM course offers complete information about warehouse and inventory processes thus making the participant an expert SAP EW Consultant.

Uplatz's SAP EWM online training helps the participants to successfully go through the SAP EWM certification provided by SAP. Uplatz provides appropriate teaching and expertise training to equip the participants for implementing the learnt concepts in an organization. Uplatz Course Completion Certificate will be awarded upon the completion of the SAP EWM course training.

The SAP EWM certification exam verifies that the participants possess basic knowledge and can prove their skills in the area of SAP Extended Warehouse Management. This SAP EWM certification exam validates that the participant has an overall understanding about this consultant profile, and able to implement the knowledge practically in projects.

Below given are the certification details of SAP Certified Application Associate-SAP Extended Warehouse Management 9.5

· Certification Level: Associate

· Exam Name: SAP Certified Application Associate- SAP Extended Warehouse Management 9.5

· Exam Code: C_EWM_95

· Exam Mode: Online

· Total Number of Questions: 80

· Pass Score: 65%

· Time Duration: 180 Minutes

· Exam Price: $550

The SAP EWM Consultant draws an average salary of $125,250 per year depending on the knowledge and hands-on experience. The SAP EWM Consultant job roles are in high demand and make a rewarding career.

The SAP EWM Consultants are recognized across the globe. The increased demand for warehouse processes in many companies help the participants to find a job opportunity easily. The leading companies hire SAP EWM Consultant considering the skill of managing the warehouse processes in an organization. The Learners earn most beneficial SAP EWM certification through our expert training and course curriculum. Being SAP EWM certified is definitely valuable credential and adds value to every organization.

The SAP EWM certification is targeted to those participants who are from SAP ERP and business background and wish to excel as SAP EWM consultant

The following are the job titles in SAP EWM domain:

· SAP EWM Expert

· SAP Warehouse Associate

· SAP EWM Consultant / End user

· SAP Warehouse Manager

· Warehousing Consultant

· SAP EWM/WM/MM/PP Consultant

· SAP Logistics Consultant

· ERP Professional

The SAP EWM online course provides you an opportunity to explore career opportunities as SAP EWM Consultant / End user.

1) What are the different deployment alternatives in EWM?

SAP EWM can be considered as deployed in ERP server or you can also recollect it as an software in Supply chain Management panorama.

SAP EWM is included with ERP to get an access to transaction and master records and use of features like slotting; availability test also requires integration with CRM.

SAP EWM is taken into consideration as separate utility and proportion the identical server with SCM applications. You also can run SAP EWM in its personal SCM surroundings that's appropriate to get improved overall performance.

EWM Deployment alternatives −

- SAP EWM on SCM Server

- SAP EWM as Standalone

2) How can you create a work center for packing in SAP EWM device?

To create a work center for packing, you need statistics −

- Warehouse

- Storage Type

- Inbound Section

- Outbound Section

If you want to define a work center, navigate to Extended Warehouse management → Master Data → Work Center → Define Work Center

3) What is Storage Control and what are its kinds?

Storage control is used to decide product actions in a warehouse. It is used to execute put away or stock removal system in the warehouse.

- Layout Oriented

- Process Oriented

4) What is Replenishment in SAP EWM?

Replenishment is described as the movement of goods from warehouse to shipment locations. In SAP EWM, you could use predefined strategies for replenishment of storage bins. There are different replenishment manage fields described at storage kind level or storage bin stage. The statistics for control fields may be entered manually inside the device or you may use a slotting system to outline these fields.

5) A benefit of using Physical inventor in SAP EWM?

To perform financial accounting and tax rules, you could need to carry out an accurate stock to get the price of an inventory in the warehouse. Physical inventory process offers with counting physical stock of a warehouse and to get counting results.

Physical inventory may be utilized by the control to count stock in order so that product can be stocked or corrected.

6) What is Slotting manner in EWM? What are special parameters used in Slotting?

Slotting is a process in EWM to outline most appropriate put-away parameters- storage type, section, etc. Slotting places the best in a warehouse in a manner that gives the most optimal storage and picking of products.

There are distinct parameters that are utilized in slotting manner −

- Storage Requirement Data

- Product Data

- Packaging Data

- Demand Forecast

7) What is Expected Good Receipts?

To create inbound deliveries expected good receipts are used. Creating goods receipt in EWM machine without an inbound delivery is also possible.

Advantages of the use of Good receipt −

This method happens in EWM machine only.

If your ERP machine is down, you could still execute anticipated goods receipt in EWM.

An expected goods receipt is based totally on statistics in production order so it could be used as the preview of goods receipt.

This system calls for two files to use in EWM gadget −

- Notification Expected goods receipt

- Expected items receipt

8) What is the goods movement status of the outbound transport after a goods issue has been canceled?

- Not yet commenced

9) Where do you manipulate Packaging specs?

Go to SAP Easy get entry to → EWM → Master Data → Packaging Specification → Maintain Packaging specification.

10) How do you perform direct Goods Issue in SAP EWM machine?

The items trouble process in extended warehouse management starts with outbound shipping request. When an outbound transport document is created, this procedure starts in the ERP system. For items which can be applicable in EWM, a delivery report is replicated in SAP EWM device.

11) What are the transactions available to create a transfer order for transferring partial shares inside a warehouse number?

- A) LT01

- B) LT10

Two transactions are available to create a transfer order for transferring partial shares inside a warehouse quantity:

- Transfer Order creation without Source Object (transaction code LT01)

- Transfer Order creation from Stock List (transaction code LT10)

12) Why do you operate Physical inventor in SAP EWM?

To perform monetary accounting and tax rules, you may want to carry out correct inventory to get the value of a stock in a warehouse. Physical inventory manner deals with counting physical inventory of a warehouse and to get counting results.

Physical inventory can be utilized by a control to matter stock in order that product can be stocked or corrected.

13) How SAP ERP device communicates with Extended Warehouse Management or CM with APO gadget?

SAP ERP and EWM are carefully incorporated with every different for a switch of transaction and master statistics. There are two ways of communication.

Core Interface (CIF) −

Core interface is one of the common strategies for communication between SAP SCM device and SAP Advanced Planning and Optimization APO. Master statistics maintained in ERP machine like customer, material, and dealer which might be had in ERP system are transferred to EWM system use Core Interface CIF communique.

14) What is Storage bin?

Storage bins represent the physical location of storage area wherein the products are stored in Warehouse. They are at the lowest stage of organization structure and whilst you keep an object in a Warehouse you have to mention its exact place.

15) What is the use of Activity regions in Storage Bin?

Storage containers are further labeled in activity vicinity. It consists of sports like choosing, placed away or a physical stock. As according to activity, you can assign identical garage bin to more than one interest areas.

16) What is Quant?

The quantity of goods in storage bin is represented by means of Quant. The quant is used for coping with inventory in a storage bin.

17) How to create a storage bin?

The storage bin can be created by using the following code

T-Code: /SCWM/LS01

18) What is the Work Center in a Warehouse?

A work center in Warehouse is assigned to a storage type and a physical unit to carry out packing, deconsolidation or weighing activities. Storage kind assigned to the work center has a role within the work center, pick out a factor or select factor and identification. You can also configure extra than work center in a storage type.

19) What are the specific components in a Value Added Order?

The following are the specific components in a Value Added Order.

- Order Header

- VAS sports to be performed

- Items

- Auxiliary merchandise (Packing material, labels, oil, and many others.)

20) What is Value Added Services in Warehouse management?

Value Added Services define the product processing to be done in a warehouse and consists of activities like packing, labeling, assembling, etc.