SAP WM (basic to advanced)

Learn Organizational structure, master data, stock transfer, stock removal, transfer orders & blue printing for your warehouse.Preview SAP WM (basic to advanced) course

View Course Curriculum Price Match Guarantee Full Lifetime Access Access on any Device Technical Support Secure Checkout Course Completion Certificate 53% Started a new career

BUY THIS COURSE (GBP 29)

53% Started a new career

BUY THIS COURSE (GBP 29)

-

79% Got a pay increase and promotion

79% Got a pay increase and promotion

Students also bought -

-

- SAP WM (Warehouse Management)

- 30 Hours

- GBP 29

- 1523 Learners

-

- SAP WM (comprehensive)

- 15 Hours

- GBP 29

- 381 Learners

-

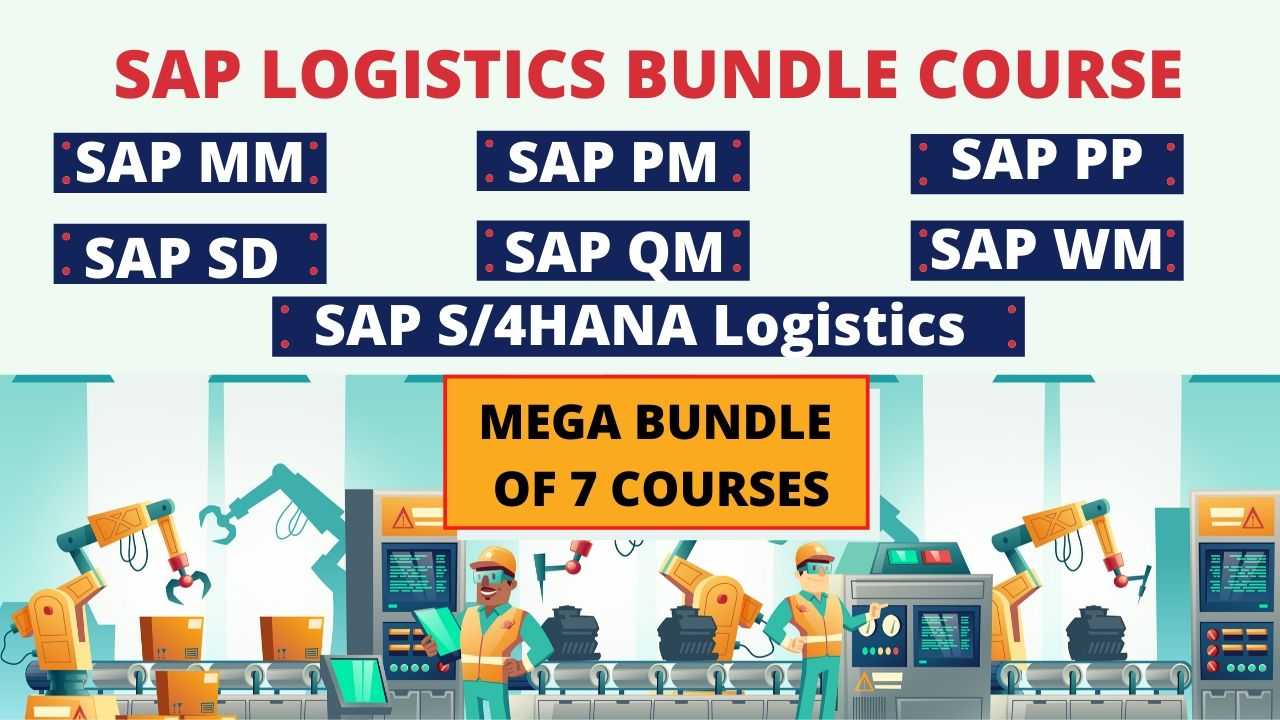

- Bundle Course - SAP Logistics (PM - PP - MM - QM - WM - SD - S4HANA Logistics)

- 200 Hours

- GBP 22

- 1692 Learners

The SAP Warehouse Management system (WM) module provides flexible, automated support in processing all goods movements and in managing stocks in your warehouse complex. The system supports scheduled and efficient processing of all logistics processes within your warehouse.

It handles the warehousing processes like Define and manage complex warehousing structures, Optimize material flow using advanced put away and picking techniques, Process goods receipts, goods issues and stock transfers quickly and easily etc.

With Uplatz’s SAP WM course you will gain skills on the configuration and management of SAP WM module and will be able to do the following by the end of this SAP WM course:

1) Manage complex warehouse structures

2) Define and manage storage areas and storage bins in the warehouse

3) Manage several different types of storage, such as high rack storage, block storage or fixed bin storage

4) Process all relevant postings and transactions such as goods receipts, goods issues and general stock transfers

5) Monitor stock movements

6) Execute stock placements and removals using different put-away and picking strategies

7) Process stock differences

8) Manage hazardous materials

9) Use bar code scanners

10) Interface to external non-SAP warehousing systems

11) Manage inventory at the storage bin level

12) Ensure that stock posted in the Inventory Management system is the same as the stock in the warehouse

13) Integrate with materials management, product planning, quality management and sales and distribution

Course/Topic - SAP WM (basic to advanced) - all lectures

-

In this tutorial we learn about SAP WM. We give you a basic introduction about SAP WM. In this lecture session we also talk about some functions of SAP WM.

-

In this lecture session we talk about organization structure in WM and config settings in the SAP WM.

-

In this lecture session we talk about Manual creation of WM and also talk about best techniques of creation of WM manually.

-

In this lecture session we learn about WM with MM. In this tutorial we talk about display material documents.

-

In this tutorial we talk about basics to advance in SAP WM. We also cover WM with IM in this SAP WM Lecture session.

-

In this lecture session we learn about from Q.I stock to available stock and also talk about transfer material from material to material in SAP WM.

-

In this lecture session we learn about the Physical inventory process in WM with IM in the SAP WM.

-

In this lecture session we learn about Physical inventory process and automatic and TR TO and TOO and also talk about basics of SAP WM.

-

In this lecture session we learn about stock transfer in WM and putaway strategies and also talk about best techniques of transferring stock in WM.

-

In this lecture session we learn about putaway strategies and batch management in WM and also cover all the best strategies of SAP WM.

-

In this lecture session we learn about WM with SD - stock removal strategies or picking strategies in SAP WM.

-

In this tutorial we talk about the two step picking process. In this process stock removal is divided in two steps.

-

In this lecture session we learn about monitoring WM stock overview and also cover two steps of picking the stock.

-

In this lecture session we learn about STO in WM stock removal and also cover basics about the interface of WM.

-

In this lecture session we talk about WM interface and master data in PP and also talk about how we enter and manage the master data.

-

In this tutorial we learn how we maintain the master data in SAP WM and also cover WM in PP and after maintaining above master data run the pp cycles.

-

In this lecture session we talk about material staging for the production supply in master data in SAP WM.

-

In this lecture session we learn about WM integration with QM and allow negative stock in WM and also cover advance level strategies in SAP

-

In this lecture session we learn about how in industries we will receive and ship material based on pallets.

• Understand the concepts of SAP Warehouse Management system

• Understand Organizational structure and master data

• You will be able to perform end to end transaction on SAP WM

• You will understand in detail regarding picking and put-away strategies

• Clear your concepts on good receipts, good issue, stock transfer, stock removal, transfer orders

• Understand customisation in WM

SAP Warehouse Management (basic to advanced) – Course Syllabus

· SAP WM Introduction

· SAP Warehouse concept and org structure hierarchy

· Organization Structure in WM and Config Settings

· SAP Warehouse configuration case study - configure storage type, storage section, bin setup

· Create WM master data setup

· Manual Creations in WM - TR TO etc.

· Automatic TR TO and TO Confirmation

· Physical Inventory Process

· Configure Interface between inventory management and warehouse management

· WM with MM

· WM with IM

· Customization of movement types

· Understand the Put away control and different customization options available for put away

· Storage bin search for put away

· Forms of capacity check

· Configuring different put away strategies

· WM with QM

· Setting up WM-QM interface for Quality check in warehouse

· WM with PP

· Stock Transfers in WM

· Understand stock removal control

· Customization for stock removal

· Batch determination process during stock removal process

· Putaway Strategies

· Configuring different picking strategies like FIFO, stringent FIFO etc.

· Understand Posting changes

· Understand Inbound, outbound and post change processes with WM integration

· How to create and process of Transfer requests, transfer orders and PCN documents for a warehouse

· Stock Removal Strategies

· Batch Management in WM

· How to do Replenishment setup in warehouse

· Setting WM-PP interface for internal procurement

· Setting up Warehouse activity monitor

· Customization for physical inventory

· Carrying out physical inventory

· WM with SD

· Picking Strategies

· Two Step Picking Process in WM

· STO in WM

· Storage Unit Management (SUM) in WM

The SAP WM (basic to advanced) Certification ensures you know planning, production and measurement techniques needed to stand out from the competition.

SAP Warehouse Management (WM) is an important SAP module that provides warehouse management functionality. This module provides tools & processes to maintain inventory at optimum level.

In a delivery, the WM status is 'B' (Partially Processed) even though all WM activity appears to be completed. One or more delivery items has WM status 'B' even though there are no open transfer orders associated with the delivery.

It covers the procurement process, master data (material and vendor master record), account determination and item evaluation, inventory management, invoice verification, business needs planning articles, etc. Up skill with #SAP Extended Warehouse Management.

Uplatz online training guarantees the participants to successfully go through the SAP WM (basic to advanced) Certification provided by Uplatz. Uplatz provides appropriate teaching and expertise training to equip the participants for implementing the learnt concepts in an organization.

Course Completion Certificate will be awarded by Uplatz upon successful completion of the SAP WM (basic to advanced) online course.

The SAP WM (basic to advanced) draws an average salary of $114,000 per year depending on their knowledge and hands-on experience.

A warehouse management system (WMS) is a software application that helps control and manage the day-to-day operations in a warehouse. WMS software guides inventory receiving and put-away, optimizes picking and shipping of orders and advises on inventory replenishment.

Generally, a warehouse is a structure or building design keeping in mind raw material and finished goods it is going to store. Therefore, warehouse management should be able to: Receive the purchase goods and enter upon the stock register.

Note that salaries are generally higher at large companies rather than small ones. Your salary will also differ based on the market you work in.

SAP HANA Design Specialist.

SAP - IBP - Senior Associate.

SAP ABAP Development for HANA Application Developer.

Q.1 What is Transfer Requirement?

Answer: An instruction to move materials from a source storage bin to a destination storage bin in a warehouse complex at a specified time.

Q.2 What is Transfer Order?

Answer: A request to transfer of materials at a particular time from source storage bin to Destination storage bin in same warehouse complex.

Q.3 On what basis a TO will get generated?

Answer: On Movement Types

Q.4 Which one will the system generates first, TR or TO?

Answer: First TR then TO.

Q.5 At What level the release strategies gets defined?

Answer: Configured at Company code level.

Q.6 What are different Movement Types.

Answer:

101 – GR Receipts

102 – GR PO reverse

601 – GI delivery

602 – Cancel GI delivery

651 – Sales return

909 – GR Amendment Excess

Q.7 Different stock types and storage types in WM?

Answer: Stock Types – Unrestricted, Blocked, Quality Storage Types – Rack, Open, Shelf, Damage

Q.8 Interim Storage types?

Answer: Goods Receipt area, Goods Issue area, Posting change, Difference.

Q.9 Where you do the stock comparison between IM and WM?

Answer: T-code LX23

Q.10 Storage location is IM or WM component?

Answer: IM

Q.11 Different types of picking and put away strategies, why? Justify.

Answer: Picking

FIFO – To sale the oldest material first

LIFO – To sale the latest material first

Put away: Next empty bin, addition to the existing stock, mixed storage, fixed storage, open storage.

Q.12 Difference between Storage units and Handling units.

Answer: Storage unit is a container in which a material stored or transported where as Handling unit the combination of material and Packaging material.

Q.13 Why one should create a Second TO in WM.

Answer: Second TO has to be created at delivery level to move the stock from intermediate storage type to Goods issue (delivery) area for loading the stock into vehicle.

Q.14 Can you configure the automatic TO creation at all document level?

Answer: Yes.

Q.15 Where do you configure the strategies for Put away and Picking?

Answer: SPRO-> Logistics Execution-> Warehouse Management -> Strategies -> Define Put away Strategies and Logistics Execution-> Warehouse Management -> Strategies -> Define Stock Removal Strategies

Q.16 Explain Warehouse Structure

Answer: Warehouse structure contains a Warehouse number, Storage types, Storage sections, storage bins and finally quant.

Q.17 Can a single warehouse could be configured for more than one company code?

Answer: Yes it can be.

Q.18 Tell me the different picking and put away strategies defined for xyz Client for different storage types.

Answer: For Rack, Open and shelf storage types the picking strategy is FIFO.

Put way strategy for Rack, Open, Shelf, CRD and Fixed Bin is Next empty bin, Open storage, open storage, open storage and fixed bin respectively.

Q.19 Can you tell me what all documents get created during GR entry in WM Process?

Answer: PO, Inbound Delivery, Transfer Requirement, Shipment and TO.

Q.20 Where is control to confirm TO for Put away and Picking?

Answer: Control to confirm TO for Put away and Picking can be configured at Warehouse, Storage types and Movement types levels.

Q.21 Stock Uploading will happen at which Module MM or WM at rollout in xyz client?

Answer: First in IM(MM) then in WM

Q.22 Is Storage unit activation mandatory?

Answer: Its not mandatory

Q.23 What is the importance of Quant number?

Answer: when ever u do the GR system will generates one Quant number based on the combination of Material, Batch, and Bin.